Equipment

Built for Today. Designed for Tomorrow.

Every LINK product is designed by a cross-functional team of veteran engineers who solve real customers’ problems in our own test laboratories every day. There is no substitute for this hands-on experience. It’s built into every test system we make. For that reason, our custom engineering solutions and equipment can simplify and improve your processes.

LINK equipment is engineered, manufactured, and assembled under our own roof here in the United States. Though we offer a wide variety of time-tested standard equipment, our specialty is developing innovative custom solutions for your most complex and demanding applications.

Because LINK machines are built to last, you can plan on 30 or more years of service. We design every system to stay relevant far into the future, remain backward-compatible, and be easily adaptable to tomorrow’s needs with only minor upgrades. That’s why LINK delivers the lowest amortized cost of ownership in its class.

There is no substitute for whatever your application or testing needs are. We have the equipment, testing expertise, and superior support to position you for success. Our promise is to provide you with the smartest testing and custom engineering solutions.

Looking for testing solutions? Click here.

Other Link Group Companies

Showing 49–60 of 97 results

-

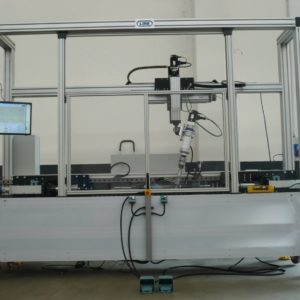

End of Line Steering Rack Function Test System

-

Three and Five Axis Steering Rack Durability Test Systems

-

Impact Test System

-

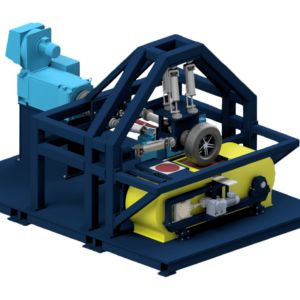

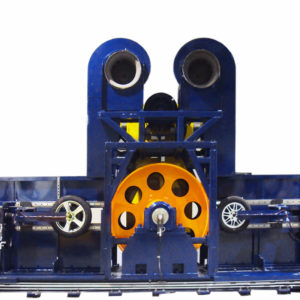

321 Flat Belt Machine

-

Tire / Wheel Moment of Inertia and Center of Gravity Machine

-

Cleat Testing and High-Speed Uniformity

-

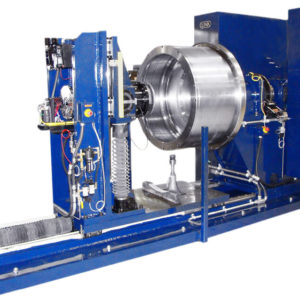

Model 3830 Wheel & Tire Radial Load Machine

-

Model 1230 Wheel Impact Tester

-

Model 3536 Biaxial Wheel Fatigue Test Stand

-

Model 1750 & 2500 Wheel and Brake Cornering & Rotary Fatigue Machines

-

Model 3546 Wheel Bearing Test System

-

Model 3928 Bearing Endurance Test Machine

LABORATORY INFORMATION

MANAGEMENT SOFTWARE

LabLINK is a comprehensive and modular LIMS, and is now available worldwide!