Equipment

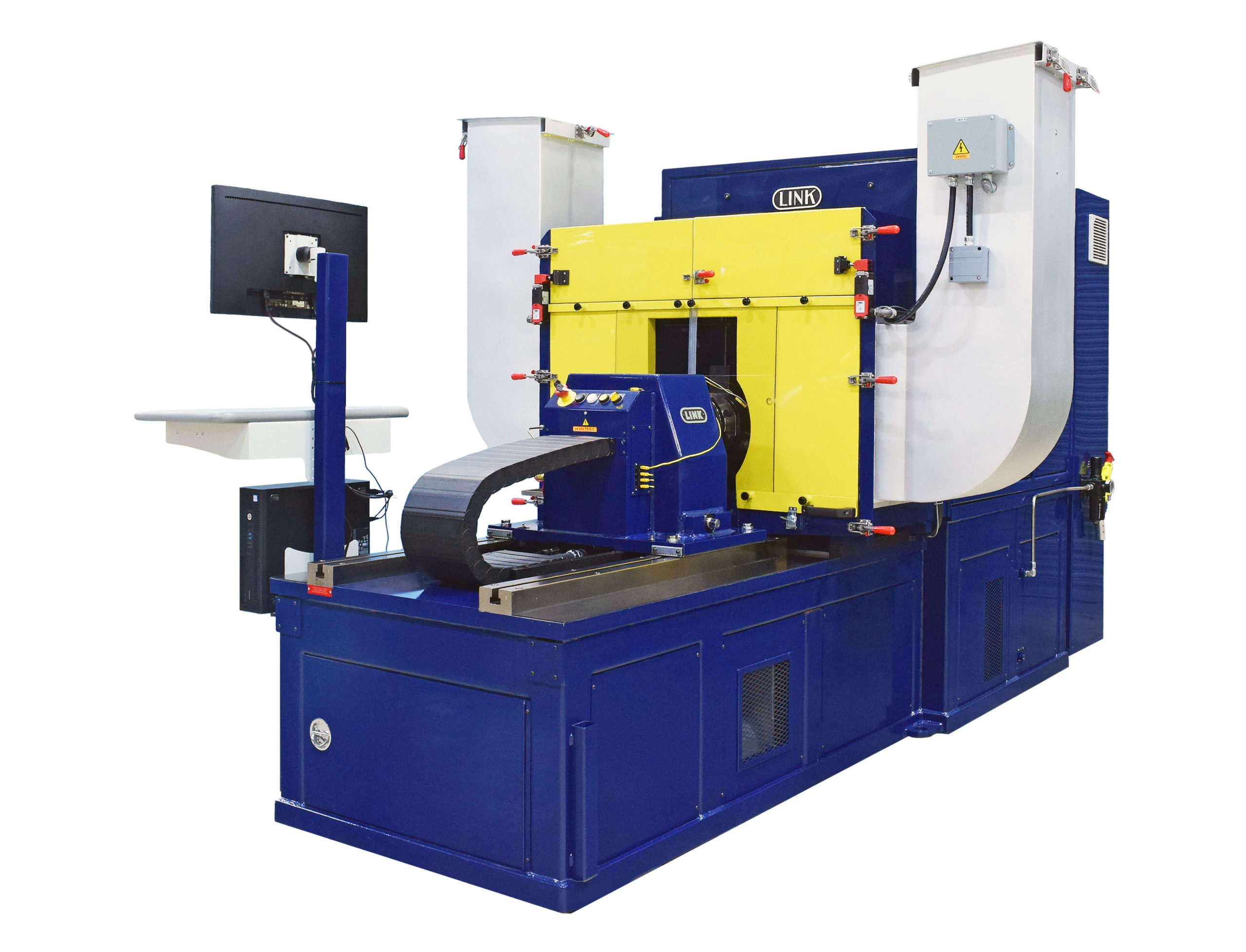

Model 2000 Friction Standards Dynamometer

Overview

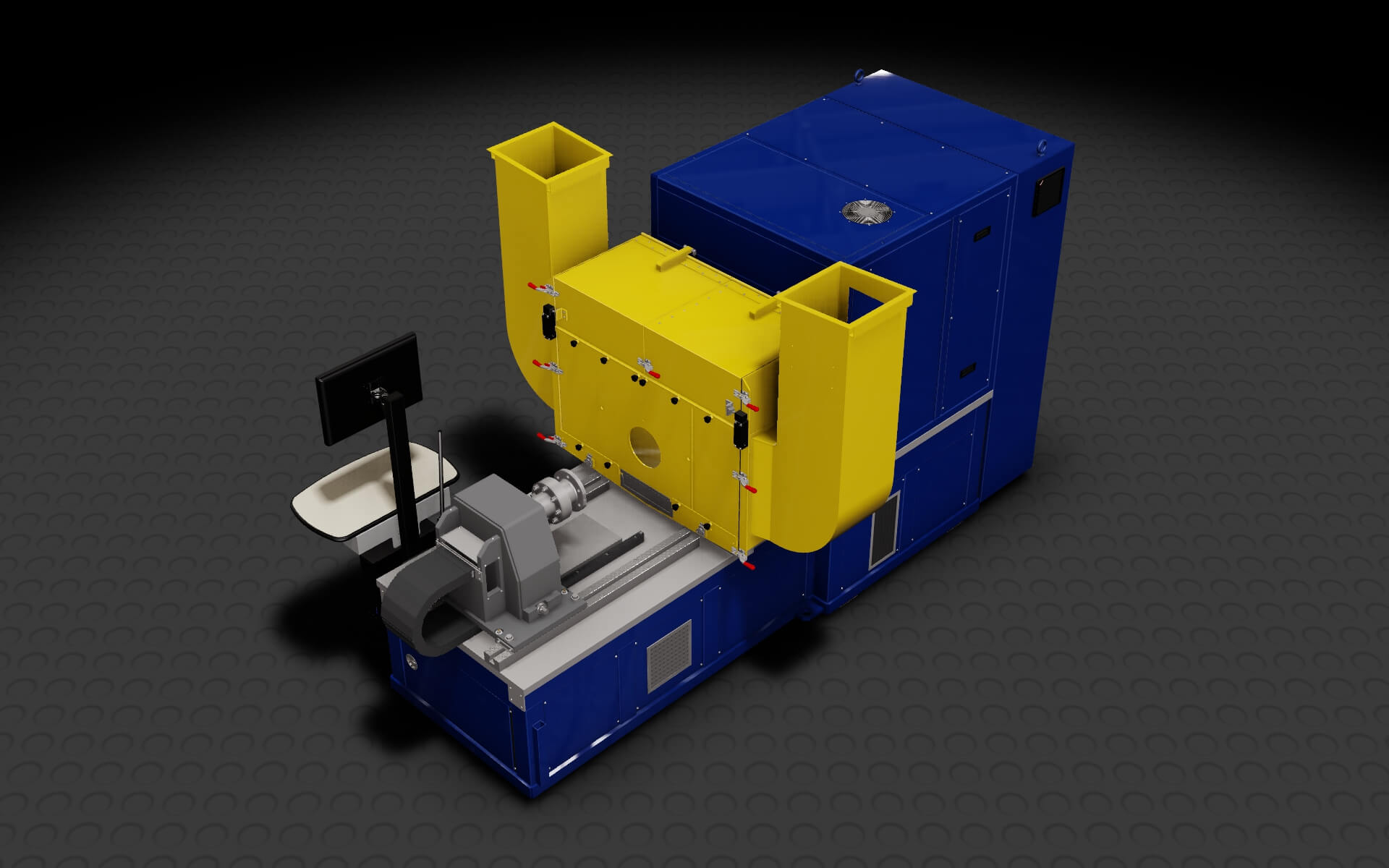

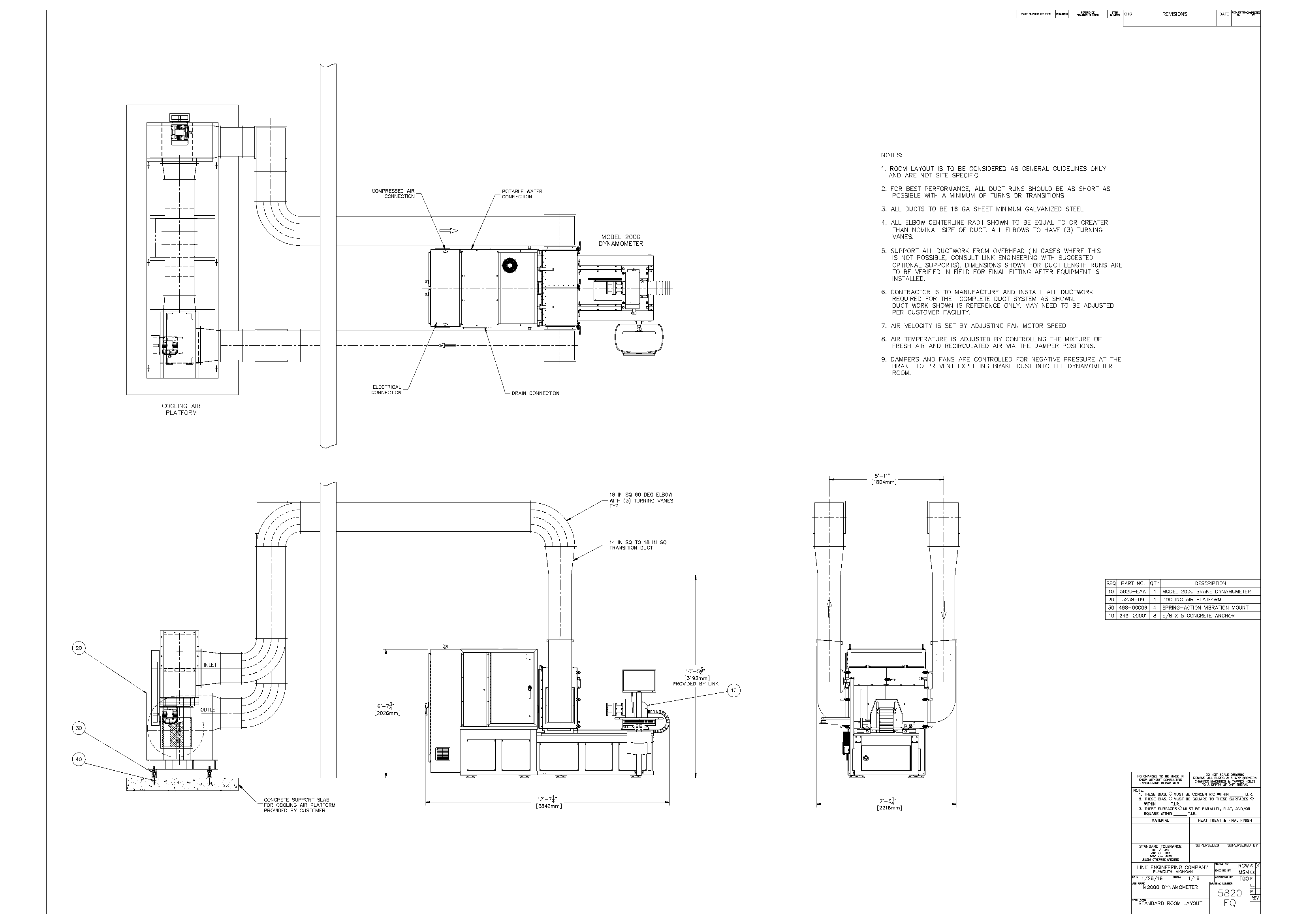

The Model 2000 Friction Standards Dynamometer (Model 2000) is designed specifically to conduct the most commonly run global test procedures for development of hydraulically actuated brake calipers, friction materials, drums and rotors for passenger vehicles and light trucks. Its compact layout efficiently and economically allows evaluation of brake friction development, design and quality control.

The Model 2000 incorporates the latest technology, software, controls and proven components, which result in low maintenance. It is an excellent value at an affordable price point, and comes with the added benefit of having a short lead-time for fast delivery, while saving time and cost for installation.

The controls enable close correlation with existing test protocols. The ProLINK software package offers manual operator control, or fully automatic unattended operation. The operator can select test parameters, control modes, display data, monitor test functions and execute desired test sequences.

Key Benefits

- Excellent value at entry level price point, with short lead-time and fast delivery

- Latest technology software and controls

- Proven components with low maintenance

- Small footprint: Controls and power cabinet integrated onto machine as a single unit

- Ease of installation (no concrete foundation required)

- Safety interlocks on all guard doors

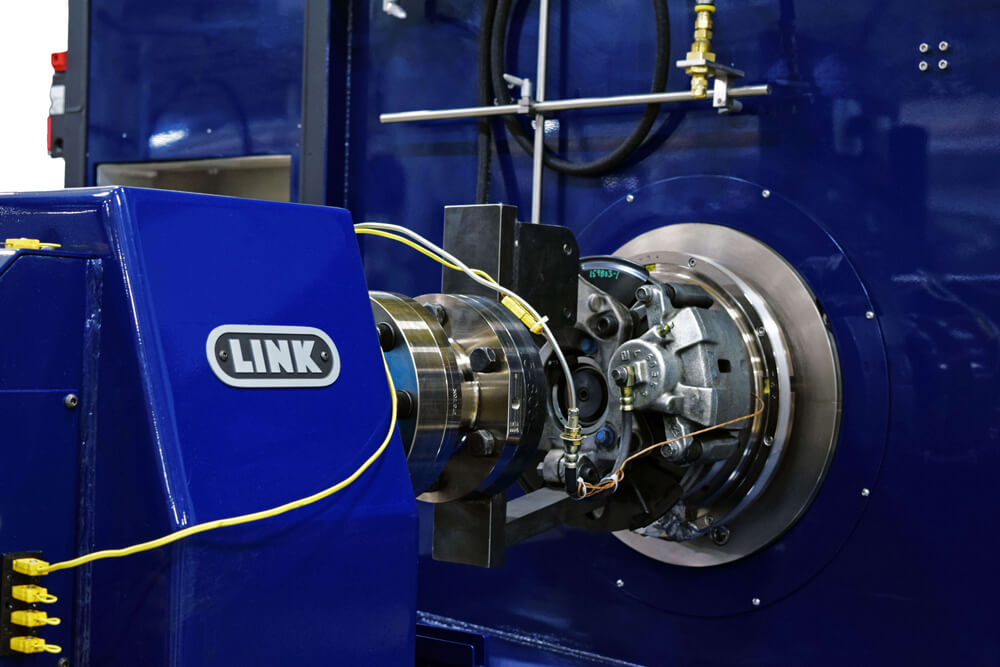

- Fold-away brake chamber for ease of access for test part setup

- In-line reaction torque sensor

- Universal fixture (caliper-disc and drum-shoes) (Optional)

- Brake knuckle test fixture (Optional)

- Calibration assembly

Test Procedures

- SAE J2522 Dynamometer Global Effectiveness dated 2014-09

- SAE J2784 FMVSS Inertia Dynamometer Test Procedure for vehicles below 4,540 kg GVWR dated

- 2007-12 (without park brake section)

- ISO 26786:2009 Friction Behavior Assessment for Automotive Brake Systems

- JASO C406:2000 Passenger car – Braking device – Dynamometer Test Procedure

- ECE R90-02:2013-Annex 9 – Part A Determination of Friction Behavior by Machine Testing

- IS0-TC22-SC2-N557 Global Spec Section 7.4 – dated 2000-10

- Performance Wear

- Fade and Effectiveness

- Thermal Roughness

- City Traffic Route Simulations