Equipment

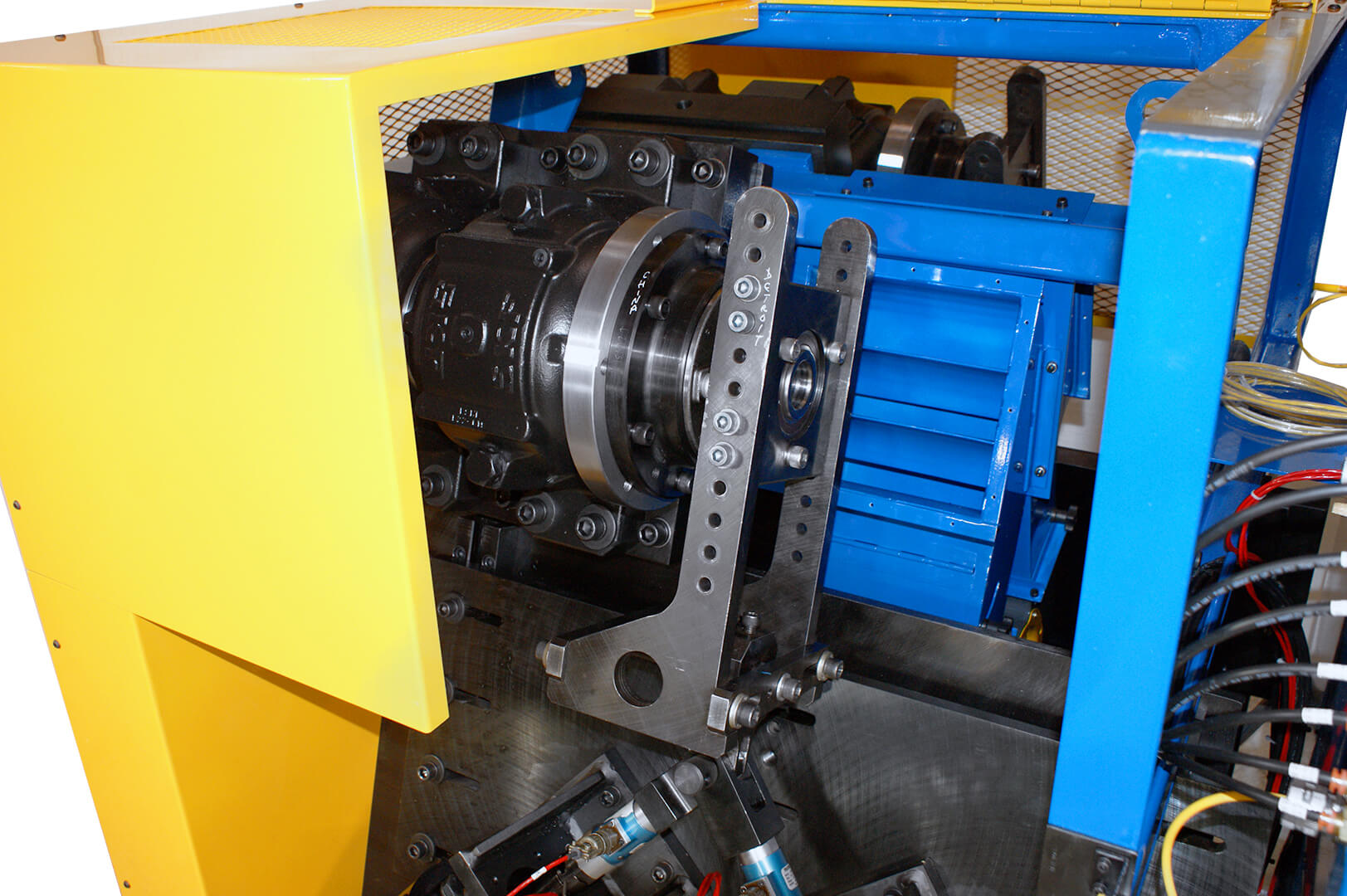

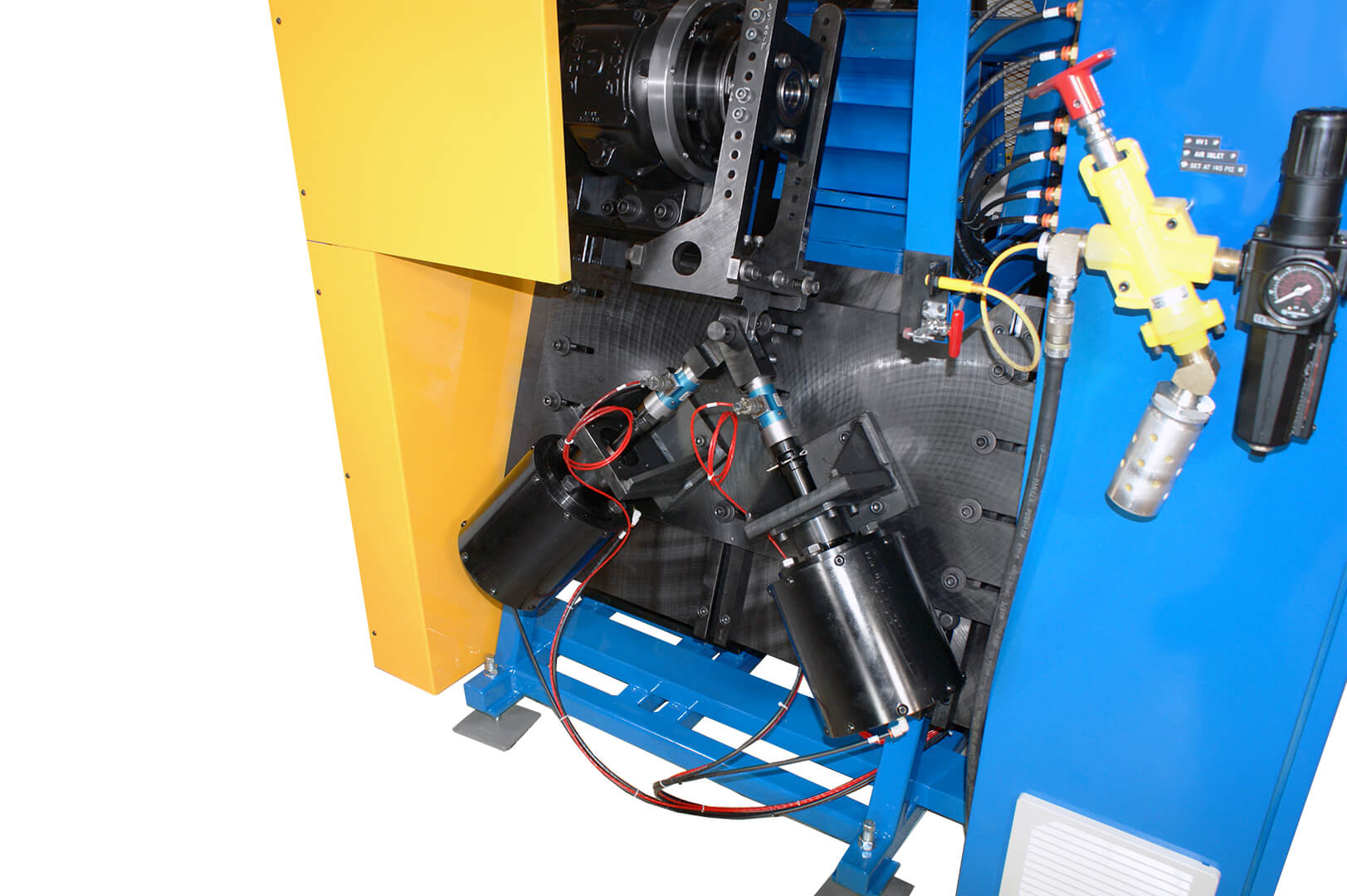

Model 3928 Bearing Endurance Test Machine

Overview

The Model 3928 Bearing Endurance Test Machine provides a sophisticated dual station test system to perform endurance testing on automotive wheel bearings. A single control system is integrated to run both test stations.

The control system maintains a constant load on each bearing assembly while rotating the test parts at user programmable test speeds. Simulated forces are reproduced via a pneumatically actuated load apply system.

The advanced features of the ProLINK software package offers operator dependent control or fully automatic unattended operation. All primary operating functions are performed at the test station including selection of test parameters, control modes, display of pertinent data, monitoring of all test functions and execution of desired test.

Ease of operation combined with accurate and reproducible measurements, make the Model 3928 an ideal instrument for control, product development research, or other endurance applications.

Key Benefits

- Accurate and reproducible measurements

- Sophisticated dual station test system with a single control system

Key Features

- 11.2 kW Motor

- 1500 rpm Max Speed

- 22,240 N Max Load Apply

- 1128 m3/hr Max Cooling Airflow

- Dual station

- ProLINK Software Suite

- Single control system