Test Equipment

Showing 49–53 of 53 results

Showing 49–53 of 53 results

Link Engineering provides links to web sites of other organizations in order to provide visitors with certain information. A link does not constitute an endorsement of content, viewpoint, policies, products or services of that web site. Once you link to another web site not maintained by Link Engineering, you are subject to the terms and conditions of that web site, including but not limited to its privacy policy.

Click the link above to continue or CANCEL

Type of Test Test Highlights Equipment Used Example Procedures

Chemical Testing Measurement of copper, asbestos and other elements in brake friction materials ICP-OES / PLM J2975

Materials Testing Physical properties including quality control for friction, wear, compressive strain, shear strength, corrosion resistance, swell and growth Chase Machine / Compressibility Machine/ Shear Machine / Corrosion Chamber / Environmental Chamber / Oven J661, ISO 6310, ISO 6311, ISO 6312, ABNT NBR 9301, ABNT NBR 5505, ABNT NBR 5537, ASTM B117

Frequency Response Component Frequency Response Laser Vibrometer Test Stand SAE J2933, J3001, J2598, L-4375

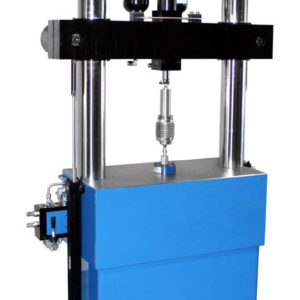

Structural Fatigue and

DurabilityBreaking strength, cyclic fatigue Servo Hydraulics, Torque Flex J2995, C419, C441, GMW18022

Caliper Fingerprinting Caliper characteristics such as knockback, rollback, fluid displacement, deflection... Caliper Test Bench / Brake Dynamometer L-4177, PF.90257

Brake Drag and DTV Residual drag, disc thickness variation, brake feel and vehicle fuel mileage Off Brake Drag Stand / Brake Dynamometer J2923, GMW14926, GMW14351, PF.90257, L-13080

Performance Hydraulic, air and electric brakes, friction levels, stopping distance, corrosion, cleanability, brake torque variation, rotor cracking, regulation, stability control, coastdown Brake Dynamometer, Model 4000 DAS J2784, J2928 IS026867, GMW14985, PF.90210, PF.90244, L-405, FMVSS 121, FMVSS 122, FMVSS 105, FMVSS 135, FMVSS 126, FMVSS 136, ECE R13H, AMS

Wear Rotor wear, drum wear, lining wear, DTV, durability, city traffic, suburban traffic Brake Dynamometer, Model 4000 DAS J2707, USCT, L-423, PF.90244, Los Angeles, Detroit, Phoenix, Birmingham, Marquette

NVH Brake squeal during drag and decel events at different temperatures, pressure and torque levels NVH Brake Dynamometer J2521, L420, 1430, GMW17427, PF. 90244

Brake Emissions Brake dust particle size, count, concentration and mass Brake Dynamometer WLTP, CARB, Duty cycle

Type of Test Test Highlights Equipment Used Example Procedures

Parking Forces Allows proper sizing of power steering components Force and Motion LINK Parking Forces

Tire Footprint Determines the contact patch geometry Force and Motion Tire Footprint

Tire Modeling

Determine tire inertia which is then used Ftire and other models and simulations Inertia Machine LINK Tire Inertial Properties

On-center parking effort test for Ftire input Force and Motion SWP

Determine static stiffness (X, Y, Z, Alpha) for Ftire input Static Stiffness Machine SAE Static Stiffness

Determine how the tire envelopes an obstacle Cleat Machine J2731

Measure the forces and moments generated at a high frequency response spindle when the tire impacts a cleat Cleat Machine J2730

Braking and Cornering Performance Determine the straight line braking performance of a tire Force and Motion J2673

Determine the free rolling cornering properties of a tire Force and Motion SAE TIME, J1987, SWP

Measure the combined cornering and braking performance of a tire Force and Motion J2675

Tire Stiffness Measure rolling vertical stiffness of a tire at speed Rolling Vertical Stiffness

Rolling Resistance Measure tire rolling resistance using a drum Force and Motion, Rolling Resistance J1269, J2452

Tire Wear Assess tire wear in the lab Force and Motion LINK Wear Test

Tire NVH Test tire sizzle, cornering noise, pass-by noise, steering wheel dither, freeze crack impacts, high speed uniformity and imbalance sensitivity Force and Motion, Dynamometer, Model 4000 DAS Noise, Vibration, Harshness

Type of Test Test Highlights Equipment Used Example Procedures

Chemical Evaluates filiform corrosion on painted aluminum wheels and painted aluminum trim ICP-OES ASTM E3061

Wheel Corrosion and Coatings Evaluates filiform corrosion, tape adhesion, degree of rusting on painted aluminum wheels and painted aluminum trim Corrosion Chamber SAE J2635, ASTM B368, ISO 9227,

ISO 2409, ASTM D3599,

ABNT NBR 11003, ASTM D610,

ASTM D1654

Wheel Fatigue Load simulation test of aluminum alloy wheels Biaxial BMW QV36026, SAE J2562, FORD

L-307, GMW14340

Dynamic Cornering Fatigue and Dynamic Radial Fatigue - Steel wheels Eccentric Mass and Radial ABNT NBR 6750

Rotational fatigue, Radial load fatigue and biaxial load fatigue of steel and aluminum wheels Eccentric Mass, Radial and Biaxial ABNT NBR 6751

Dynamic Cornering Fatigue and Dynamic Radial Fatigue and Impact resistance of temporary use and normal highway use aluminum wheels Eccentric Mass, Radial and Drop Test ABNT NBR 6752

Wheel Radial Fatigue Radial GMW14909

Wheel Impact Wheel Inboard Rim Flange Vertical Impact Drop Test GMW15321

Wheel radial impact Drop Test CETP 04.04-L300

Wheel Lateral Impact Drop Test GMW14910, SAE J175

Wheel Stiffness Frequency Response Function (FRF) Frequency Response GMW14876

Deformation of the wheel Servo Hydraulics J2315

Center cap heat

resistanceCenter Cap deformation under elevated temperature conditions Bench Test Brake Heat Center Cap

Type of Test Test Highlights Equipment Used Example Procedures

Wheel Bearing Water intrusion and durability when exposed to mud and salt Bearing Test Stand LINK Hub and Bearing, GMW16306, GMW16310

Passenger car, sport/performance and open bed vehicle wheel bearing spalling Bearing Test Stand GMW16311, GMW16308, GMW16309

Brinelling resistance validates long-term reliability/durability Bearing Test Stand GMW16305

Rotary fatigue life Rotary Fatigue Machine GMW16325

Wheel Hub Rotary bending fatigue life characteristics Rotary Fatigue Machine GMW14249

Hub/Bearing Evaluate hub and bearing performance, durability, seals and NVH when exposed to extreme environmental effects such as temperature and mud/salt solution Bearing Test Stand/Rotary Fatigue TIP-000037A, LINK Hub and Bearing, SAE J1095, LINK Impact

Hub Fatigue Hub fatigue using biaxial loading Biaxial Test Stand SAE J2562

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.