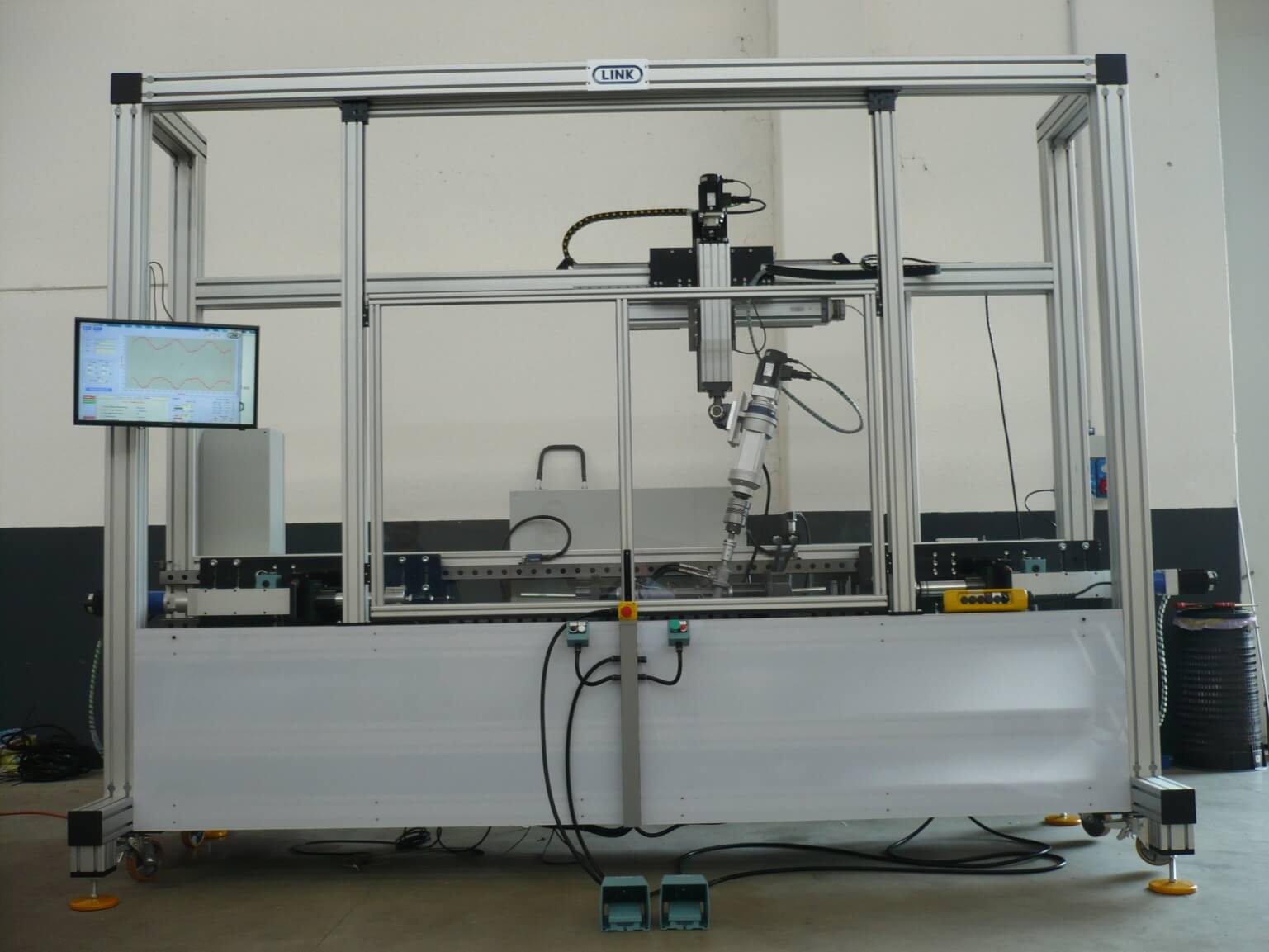

Equipment

End of Line Steering Rack Function Test System

Overview

End-of-Line (EOL) testing requires test stands in the production line, often evaluating every item produced. These conditions necessitate a more rugged construction than the test lab, and LINK’s End-of-Line Steering Rack Function Test System machines are well suited for this environment. The test stand has a clamping device capable of mounting quickly a large number of different steering gears with different dimensions while minimizing the mounting time and total test time (total test cycle is about 7 minutes).

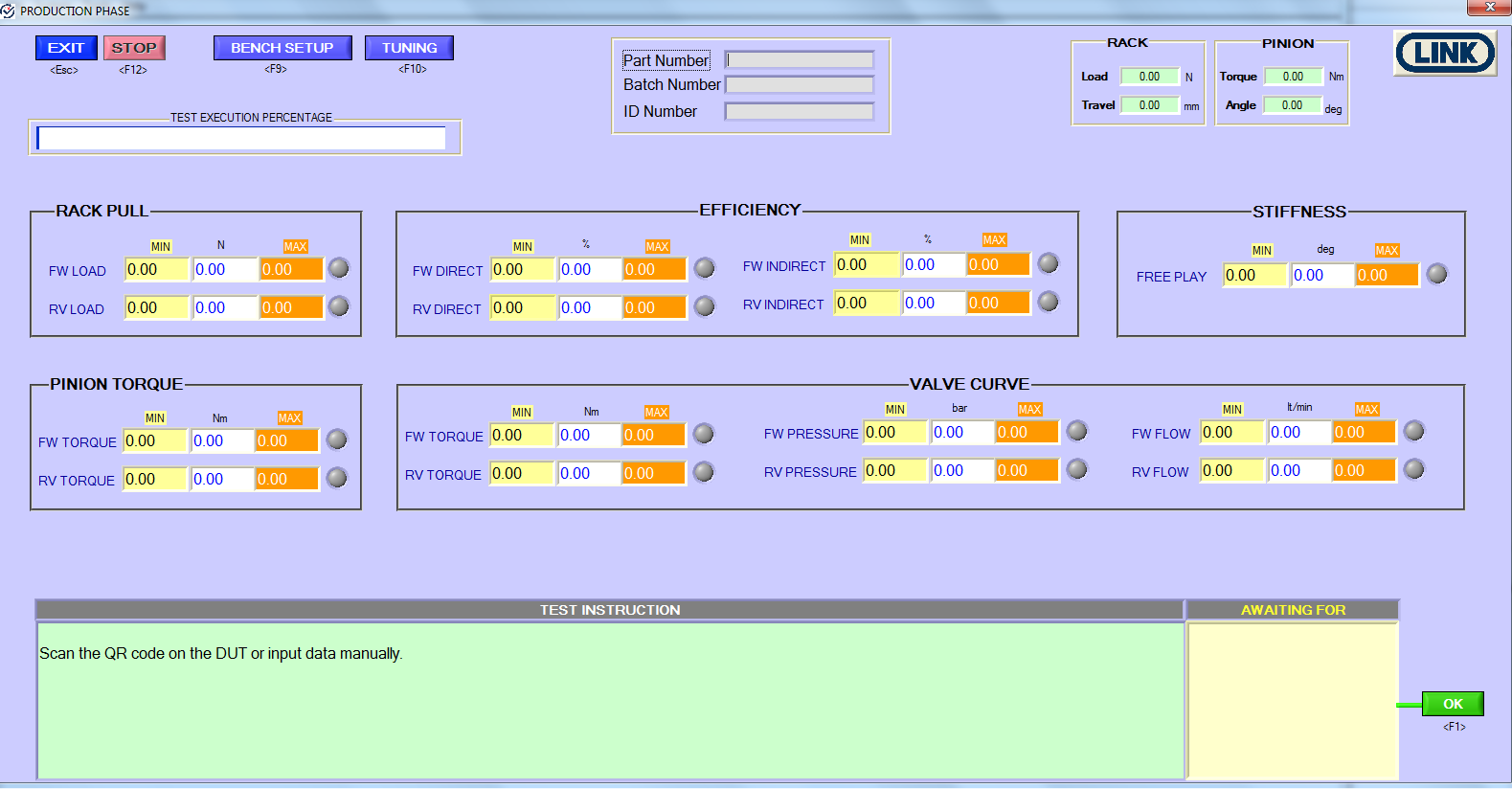

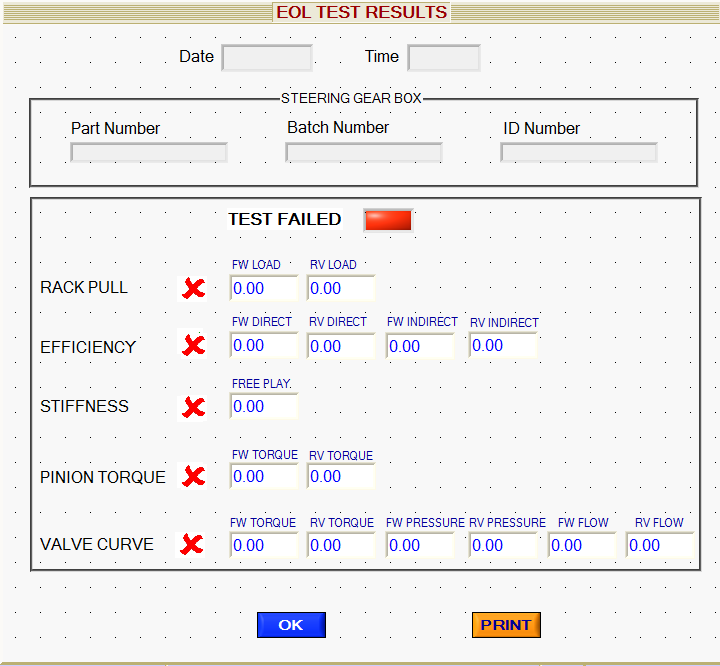

In this application, the pass-fail criteria for each part number are stored in a database; the results of each test are compared to these pass-fail criteria, summarized, and then saved in the database. An off-line analysis allows to determine the most frequent failures and if possible, correct the cause in the production process. The application software in divided in two parts:

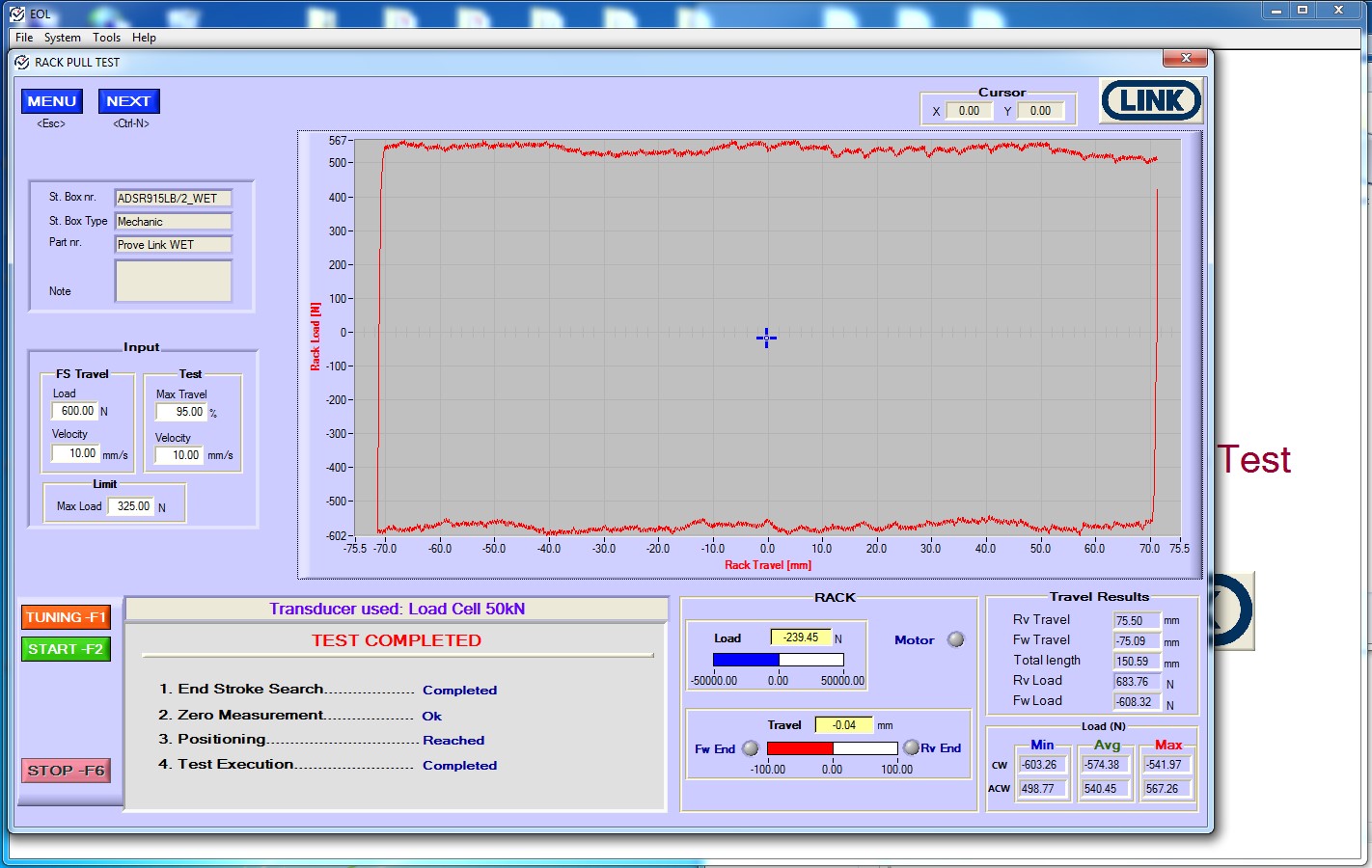

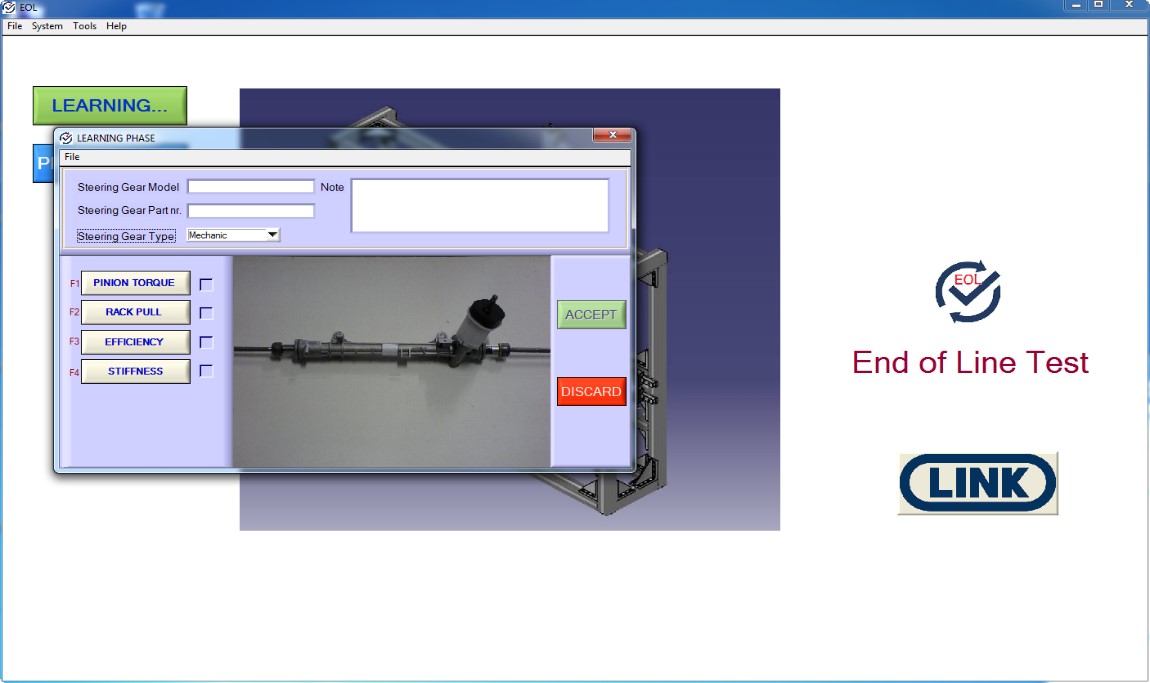

- Learning: to run a set of tests on reference DUTs and store the results in a data base to create references.

- EOL: to run a chained number of tests and compare the results with the relevant reference in data base.

The part number is scanned with a laser gun from a bar code available on the DUT. The software searches the reference part number in the data base. If found, the EOL starts the chain of test if not the system run the Learning procedure to create a new reference in the data base.

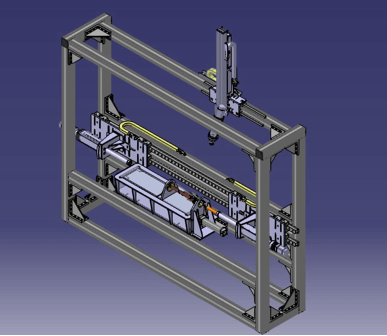

The test stand is designed for mechanical and hydraulic power assisted steering but can be enhanced to test also electric steering gears. It includes the following parts:

- Mechanical frame with two linear actuators, a rotary actuator and a universal clamping device

- Positioning units to move the three actuators in order to minimize the DUT’s mounting time

- Control electronics with digital servo and acquisition system to allow automated test execution

- Hydraulic power pack with high temperature control (100 °C) to feed oil to DUT

Technical Data

- Electro-mechanical Linear actuator : +/- 30 kN , +/- 100 mm (200 mm total stroke)

- Electro-mechanical Rotary actuator : +/- 200 Nm , +/- 1.260 degrees (+/-70° for some tests)

Key Benefits

- Grant high quality of manufactured parts

- Correct issues in the production process

- Test a large number of DUTs with different geometry and type (fixed ratio, variable ratio, right hand drive, left hand drive etc.)

Applications

- If it is not required to mount the DUT like it is on the car, the system can be used as a functional test rig expanding the type of functional test available.