Equipment

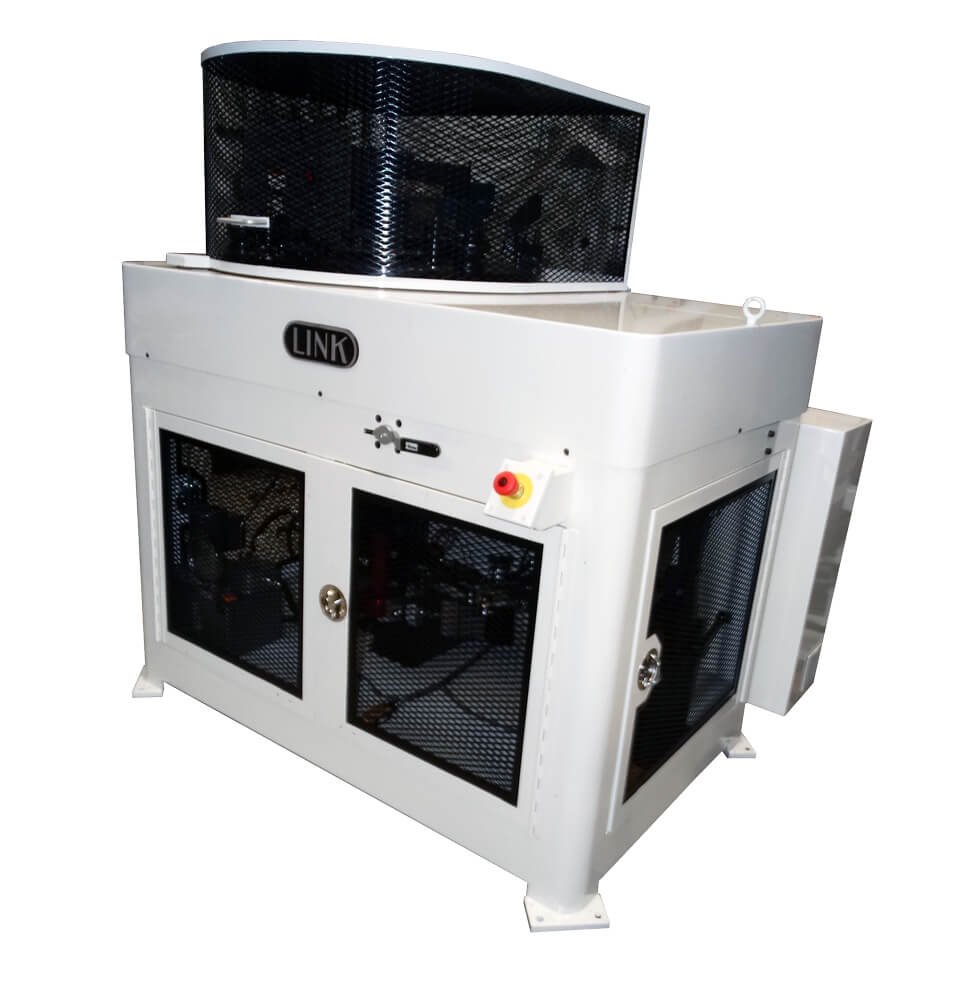

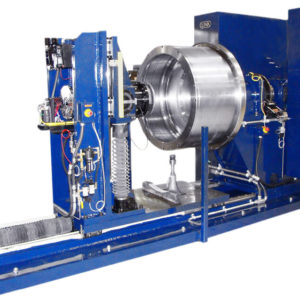

Model 1750 & 2500 Wheel and Brake Cornering & Rotary Fatigue Machines

Overview

The LINK Model 1750 and the LINK Model 2500 are designed to reproduce the forces acting on wheel and brake components as seen in vehicles by controlling the magnitude of the cornering forces consistently to determine the integrity of the test components. The control system maintains a constant force on the load arm while spinning the rotary table at the desired test speed. The test is complete when either the test part fails or the required number of rotations is reached. The load apply system is located near the base of the rotary fatigue machine.

Key Features – M-1750

- Guarding for rotating members

- Failure detection system with enunciator

The following parameter are monitored during the testing:

- Normal Load

- Load Variation

- Speed

- Revolutions

- Torque

- Travel

Key Features – M-2500

- Integral sheaves and table brake

- T-slotted plate for fixture mounting

- Guarding for rotating members

- Failure detection system with enunciator