Equipment

Model 3500

Overview

The 3500-servo controller provides a robust solution for performing dependable tests on critical test specimen. The system incorporates an intuitive Windows™ based operator interface providing the test professional a powerful, yet straightforward software. Advanced soft-start and safety control features protect both specimen and operator.

SERVICE LIFE

Our engineers have developed a controller which uses easily upgradeable hardware and proven control software to prevent continual reinvestment in controller hardware.

FLEXIBILITY

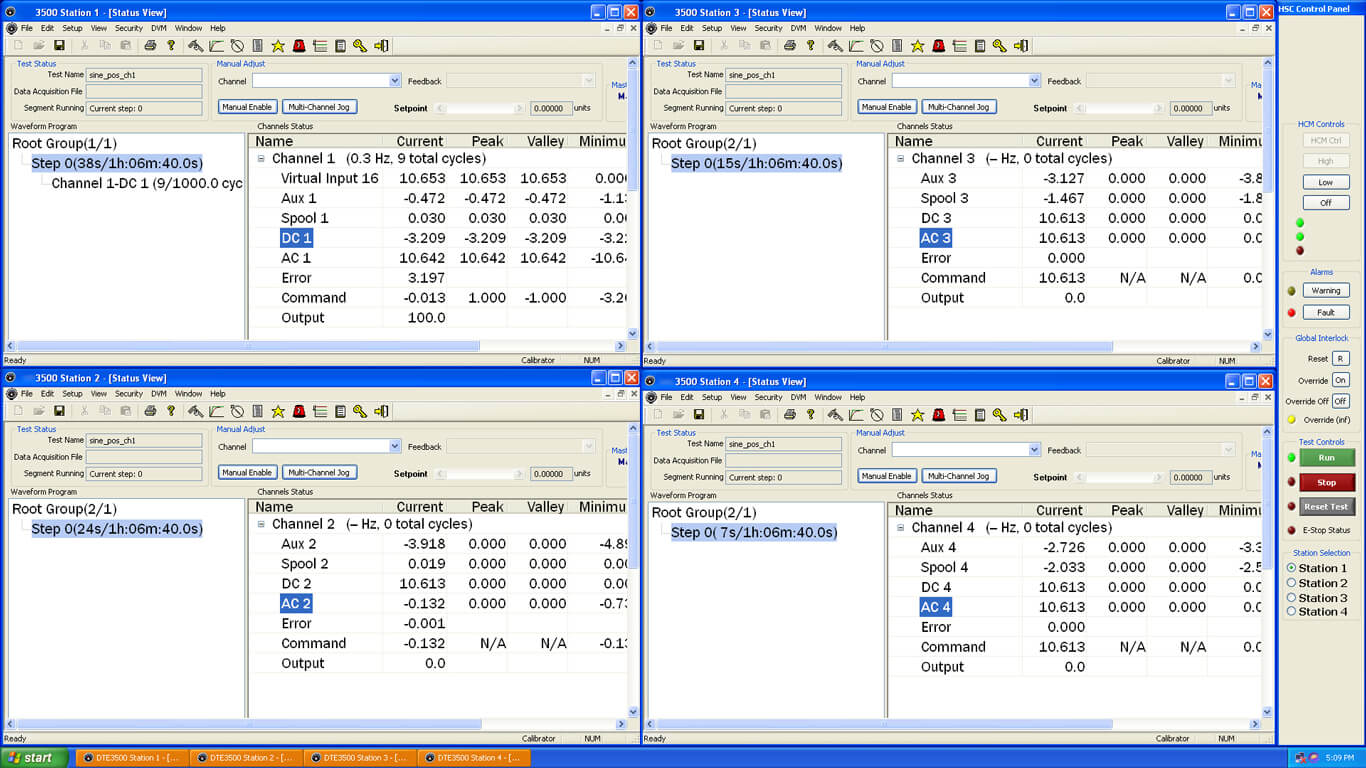

One controller supports up to eight channels and four independent stations, it is easily configurable with the ability to store and retrieve different test rig set-ups. Optional data acquisition interface allows a wide range of commercially available signal conditioning.

SIMPLICITY

Test labs need to provide accurate data as quickly and efficiently as possible. The 3500 is focused on providing simple execution of advanced tests. Intuitive set-up and industry convention have been incorporated. Contextual help screens guide operators through test set-up and operation. Station and channel configurations do not require hardware or jumper changes.

SAFETY

Redundant hardware E-stop circuit using an EIN 954-11 compliant relay allows test labs to set up OSHA compliant test systems. Configurable limits provide shut-down in case of a fault.

MULTI-STATION CONTROL

One click switching between stations allows easy control of multiple test systems. Utilizing multiple monitors reduces confusion of one control and multiple test systems. Flexible DVMs allow the operator to view the test status of all channels and stations at one time.

EASILY UPGRADE OLDER EQUIPMENT

The 3500 controller can be interfaced with older actuators and transducers. For example, we can easily interface with 200ma servo valves and valves requiring +/-10VDC command signal with 24VDC power.