Equipment

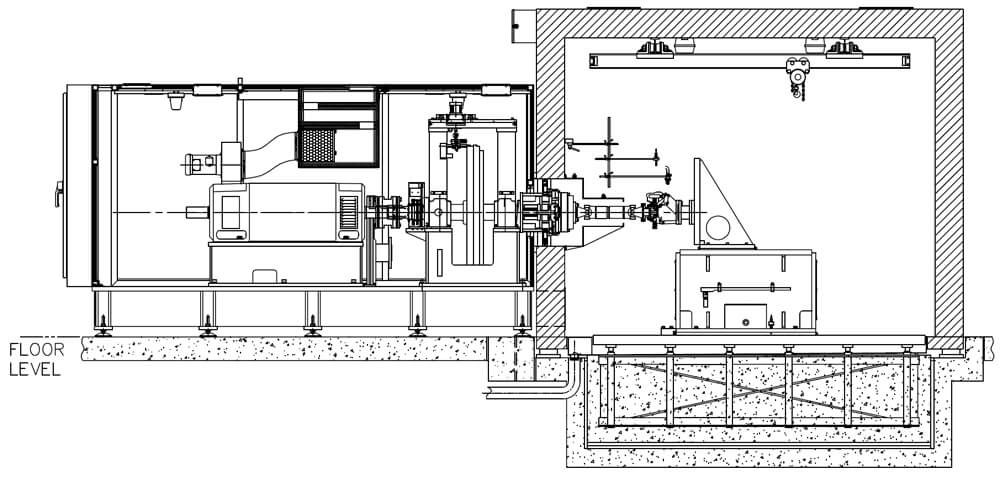

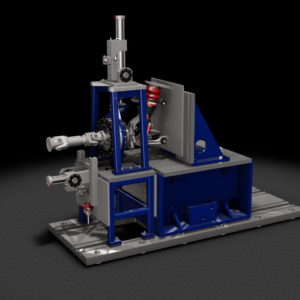

Model 3900 NVH Brake Dynamometer

Overview

The Model 3900 Dynamometer (Model 3900) is a full-sized machine specifically designed to evaluate Noise, Vibration, and Harshness (NVH) of brake assemblies for automotive and medium truck applications up to 11,300 Nm. This state-of-the-art machine incorporates a 186-kW motor capable of low speed brake drag protocols while utilizing a vehicle suspension fixture to accurately reproduce system NVH frequencies. To further duplicate on-road test conditions the suspension fixture is contained within a climatic controlled test enclosure. The test enclosure is designed as an acoustic free field chamber making the Model 3900 a perfect machine for research and development of brake system NVH. Additionally, the Model 3900 is a multi-purpose dynamometer that allows for performance brake testing. The dynamometer is fully capable to conduct all of the standard brake performance test procedures. Having one dynamometer that is qualified to conduct both NVH and performance tests can be advantageous in brake development.

Key Benefits

- Latest technology software and controls

- Proven components with low maintenance

- Controls and power cabinet Integrated onto machine

- Isolated test fixture from any machine vibrations

- Large test enclosure with free field properties

- In-line rotating torque sensor

- Suspension test fixtures

- Knuckle test fixtures

- Safety interlocks on all guard doors

- Compact pedestal workstation

- Calibration fixture for torque

- Video monitoring camera

Key Features

- Tabular step-by-step test script generation

- Customizable brake engineer graphical data review software (RevDataPlus)

- Automated reporting tools through MS-Excel

- High accuracy electric inertia simulation (I-Sim)

- Servo brake profile control

- Precision sensors for measurement: noise, vibration, shaft speed, torque, pressure, fluid displacement, brake temperature, cooling air speed, air temperature, humidity

- Integrated solution to auxiliary systems (DTV measurement, water spray, park brake testing, etc.)

- Power brake bleed system

- Environmental conditioning capabilities

- Duct silencers

- NVH measurement system